FA305C high-speed drawing frame is designed and manufactured by our company on the basis of absorbing advanced experience at home and abroad. The above models are reliable and stable in structure, with high speed, stability, high quality, high degree of electromechanical integration, and good sliver quality. The automatic simplification device selected by the user can reduce the labor intensity of the operator and improve the work efficiency. The suitable fiber length of this machine is 22-76 mm. The maximum output speed can reach 406 meters/minute.

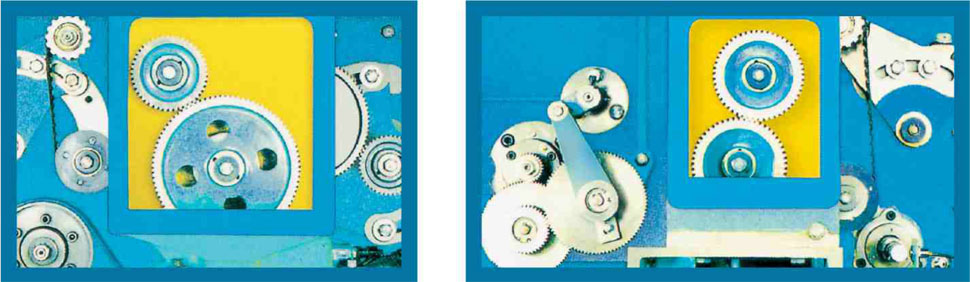

The main motor is a two-winding two-speed motor. The flat belt is transmitted to the pressure roller. At the same time, the synchronous belt gear drives other parts to ensure the accurate transmission ratio and make the operation stable and low noise. The oil bath helical gear box is used at the front and rear of the vehicle, and the pair exchange technology is used for the drafting to ensure the drafting quality.

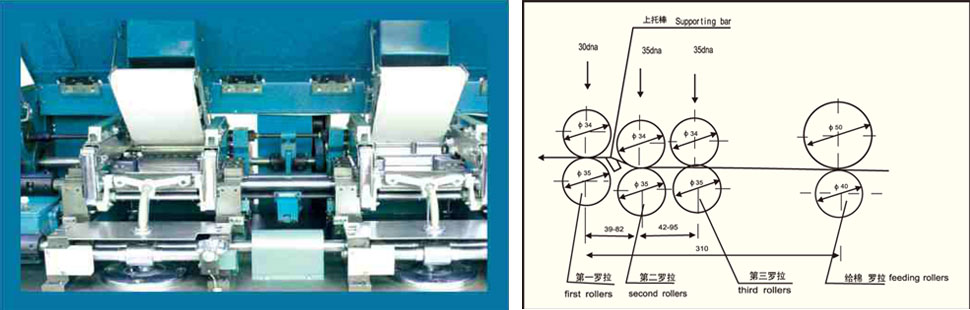

The whole machine adopts the excellent three-up and three-down pressure bar curve drafting structure, which has excellent sliver quality and stable sliver quality. The upper cleaning adopts intermittent rotary velveteen belt, and the lower cleaning adopts reciprocating swing leather ring with good cleaning effect. Processes such as cotton, wool, hemp, polyester and cotton, blended, chemical fiber medium and long fiber blended and cashmere with suitable spinning fiber of 22-76 mm.